In today’s design-driven market, furniture selection is nearly limitless. With both e-commerce platforms and brick-and-mortar retailers offering endless options, attention to detail has never been more important when choosing quality furniture components.

The desk you work at, the shelves that hold your books, and your kitchen or bathroom cabinets may all share one critical detail: edge banding.

Edge banding enhances the visual appeal of furniture, adds value, and significantly improves durability and longevity.

To help you better understand this essential yet often overlooked component, the experts at Elite Sourcing Group have created this comprehensive guide to edge banding—its purpose, applications, and the different materials available today.

What Is Edge Banding?

Edge banding refers to both a material and a process.

As a material, edge banding is a narrow decorative strip—typically with adhesive applied to one side—used to seal the exposed edges of plywood, MDF, or particle board. It improves aesthetics while protecting edges from moisture, debris, and impact damage.

As a process, edge banding is the application of these strips to unfinished edges of manufactured wood products.

How Does Edge Banding Work?

During furniture production, components such as cabinets, desks, doors, and shelving are cut to precise dimensions, leaving exposed edges. These raw edges are visually unappealing and vulnerable to moisture absorption, chipping, swelling, or cracking over time.

Edge banding seals and protects these edges, delivering both a refined appearance and long-term performance.

What Is Edge Banding Used For?

Edge banding is primarily used on manufactured wood products, including plywood, MDF, and particle board. Solid wood typically does not require edge banding, but as solid wood becomes more expensive and environmentally restrictive, manufactured panels have become the industry standard—driving the increased need for edge banding.

These panels often feature decorative top and bottom surfaces, while edge banding completes the piece by providing protection and visual continuity along exposed edges.

What Products Don’t Require Edge Banding?

Areas such as cabinet backs or drawer bottoms typically do not require edge banding, as their raw edges are hidden within dado grooves or structural joints and are not exposed to moisture or view.

How Is Edge Banding Applied?

Common application methods include:

-

Laser edging

-

Hot air

-

Hot glue

-

Iron-on

-

PSA (pressure-sensitive adhesive)

The appropriate method depends on the edge banding material, part size, production volume, and end-use requirements.

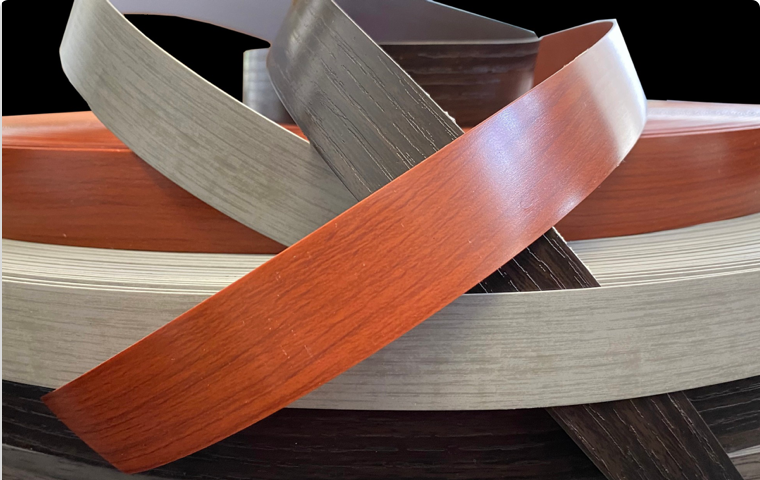

Types of Edge Banding Materials

Edge banding is available in a wide range of materials, thicknesses, widths, textures, finishes, and colors. Working with an experienced edge banding supplier ensures optimal matching and performance.

Below are the most common types:

PVC Edge Banding

PVC (Polyvinyl Chloride) is one of the most widely used edge banding materials in laminated and melamine furniture.

Best Uses

-

Modular and commercial furniture

-

Curved or contoured surfaces

Advantages

-

Durable and long-lasting

-

Cost-effective

-

Wide range of colors, textures, and sheens

-

Available in automatic, pre-glued, and PSA

PVC remains a popular choice for businesses looking to balance cost efficiency with design flexibility.

ABS Edge Banding

ABS (Acrylonitrile Butadiene Styrene) is a PVC alternative favored for its environmental benefits.

Best Uses

-

Healthcare and educational furniture

-

Architect-specified projects

Advantages

-

Recyclable

-

Thermally stable

-

Environmentally friendly

-

Wide variety of colors and textures

ABS does not release toxic chemicals when incinerated, making it a greener option.

Veneer Edge Banding

Wood veneer edge banding is made from thin slices of real wood, offering a premium natural appearance.

Best Uses

-

Cabinetry, shelving, and furniture requiring a real-wood look

Advantages

-

Sustainable and environmentally friendly

-

Stainable and finish-ready

-

Available in many species and thicknesses

-

More affordable than solid wood

Elite Sourcing Group can source virtually any wood species to meet your project needs.

Mylar & Metal Edge Banding

For a metallic appearance, mylar and metal edge banding are ideal solutions.

-

Mylar: A metal-look film laminated to PVC or ABS backing

-

Metal: Solid aluminum, stainless steel, or specialty metals

Advantages

-

Modern brushed or polished finishes

-

Available in automatic, pre-glued, and PSA

-

Mylar offers a metal look at a lower cost

Laser Edge Banding

Laser edge banding uses a co-extruded polymer layer instead of glue, creating a seamless, zero-joint finish.

Advantages

-

No visible glue line

-

Strong, durable bond

-

Compatible with laser, hot-air, plasma, and NIR systems

T-Molding

T-molding is a highly durable profile with a center barb pressed into a kerf slot.

Best Uses

-

Office furniture

-

Classroom furniture

-

Store fixtures

Advantages

-

Exceptional impact resistance

-

Maintains flexibility

-

Easy installation

Polyester Edge Banding

Polyester edge banding is a fast-growing PVC-free alternative.

Advantages

-

No formaldehyde or styrene

-

Highly recyclable

-

Excellent color accuracy

-

Multiple textures and gloss levels

Polypropylene (PP) Edge Banding

PP is considered the most eco-friendly rigid edge banding option.

Advantages

-

Safely recyclable or incinerable

-

Water and chemical resistant

-

Excellent for laboratories and schools

Melamine Edge Banding

Melamine edge banding is resin-impregnated paper designed for durability.

Advantages

-

Very cost-effective

-

Wide master rolls for flexible sizing

-

Ideal for furniture and cabinetry

Contact the Experts at Elite Sourcing Group

If you’re looking for edge banding expertise, Elite Sourcing Group is here to help. Our knowledgeable team offers guidance across materials, textures, matching, and production solutions—ensuring you get exactly what your project requires.

Tell us about your project, and we’ll guide you from start to finish.

Contact us today or request a quote to get started.