Over the past year, PVC resin prices have continued to rise due to a combination of environmental and socioeconomic factors. At Elite Sourcing Group, we believe it is important to keep our customers informed about developments in the PVC edge banding market so projects are quoted accurately and without unrealistic pricing expectations.

What Is PVC Resin and How Is It Used in Edge Banding?

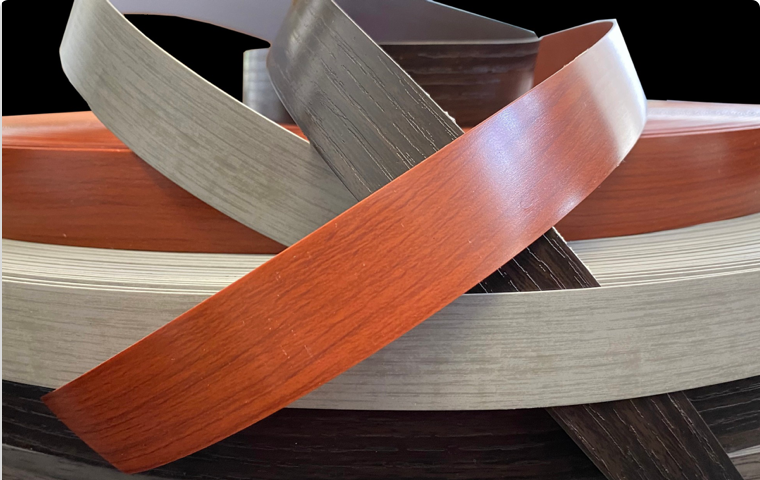

Edge banding is an extruded product made from resin, which begins in pellet form. These pellets are heated and melted during the extrusion process, allowing the material to be formed into edge banding. When heated, resin becomes soft and flexible, making it possible to print realistic woodgrain patterns. Color powders can also be added to create precise solid-color matches.

There are multiple types of PVC resins used in edge banding production, each formulated for specific applications. Some resins are designed for rigid PVC, while higher-cost specialty resins are required to produce flexible 3mm PVC. Flexible PVC is softer and commonly used when edge banding must follow contoured or radius edges rather than straight-line applications.

In addition to PVC, other resins are used in edge banding production. ABS is another plastic material commonly used to manufacture ABS edge banding. Historically, ABS resin costs have been approximately 15–20% higher than PVC. Recently, ABS resin prices have increased dramatically, accompanied by significant supply shortages from resin manufacturers.

The Rising Cost of PVC Resin

Several key factors over the past year have contributed to rising PVC resin costs:

-

In 2020, hurricanes in the Gulf region caused major disruptions to resin feedstock production. Multiple suppliers declared force majeure, leading to limited supply amid strong demand.

-

Global export demand for PVC resin increased significantly, extending lead times and pushing many suppliers to full capacity.

-

The COVID-19 pandemic resulted in higher operational costs across industries, while simultaneously increasing consumer demand for home improvement projects due to extended periods at home.

As a result, PVC resin pricing has continued to rise. Market Index Pricing (CDI) has increased by approximately 24% over the past 12 months. Since PVC resin accounts for roughly 65% of the raw material cost in edge banding production, these increases have had a substantial impact. We remain hopeful that pricing will stabilize and begin to retract within the next four to six months.

How Has Elite Sourcing Group Been Affected?

Elite Sourcing Group has not been immune to these market changes. However, we have taken proactive steps by securing PVC resin commitments to ensure continuity of supply for our customers.

While we will continue to limit price increases wherever possible, adjustments across the market are unavoidable. Our team remains optimistic that pricing conditions will improve as supply chains stabilize.

Elite Sourcing Group remains fully committed to delivering high-quality edge banding products and exceptional customer service, even as the industry navigates ongoing challenges.

If you have questions or concerns about PVC resin pricing or how it may affect your current or upcoming projects, please contact our team. We are always happy to work with you to find solutions that meet your needs.